This demonstration uses a differential of the 1/28 scale rc car, and the same method is also applicable to the 1/10 scale rc car differential.

Note: This method is only suitable for steel ball differentials, not for nitride ceramic ball differentials. The treatment methods for these two types of differentials are different.

The core of this method lies in the treatment of the differential plates. First, observe the plates and find the flatter side as the contact surface, and mark the opposite side. If both sides are equally flat, mark one of them. It is recommended to use a power tool to make a small dent or use a file to create a small notch on the edge. This is more reliable than using a pen for marking.

Next is the polishing of the plates. Install the plates onto the differential case and use 1000-grit sandpaper to polish the working surface in a circular motion until the surface shows a uniform pattern.

Then, use the backside of the sandpaper to further refine the pattern on the working surface. Rinse off the debris on the plates with cleaner and evenly apply differential oil on the surface.

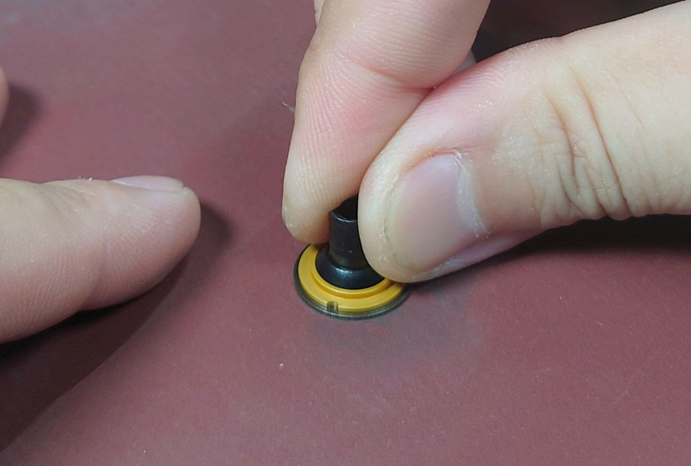

Clean the balls with cleaner, place them in your palm, add a small amount of differential oil, and rub them between your fingers to distribute the oil evenly. Then, follow the instructions to complete the remaining assembly steps.

When adjusting, it is recommended to hold the cups on both ends or secure the wheels on both sides. Use your hand to rotate the differential and adjust the tightness gradually, starting from a slipping state, until you can barely rotate the differential with your hand. Differential treated with this method will have a fine granular sensation when tightened, but it will feel very smooth and will not slip.